Why clamping down on industrial noise is a sound idea

University researcher’s innovative solution improves hearing safety in power plants

November 16, 2018

Power plants are notoriously loud places. Complex and robust piping systems support the flow of pressurized steam to turbines that help generate electricity. When the pressure reaches a certain limit, safety valves open to vent the steam, protecting the pipes from failure.

But those safety measures come with a big trade-off: the steam exits pipes at such a high velocity, it can generate noise levels louder than rock concert, and approaching airplane jets at takeoff. Brief exposure to such intense noise can cause permanent hearing damage. Even outside of the plant, the sound can be bothersome.

Vent silencers installed on pressure/safety relief valves at the steam exit point absorb noise before it escapes into the environment. Silencers typically include a diffuser, which slows the escaping steam before it passes through a sound-absorbing section. But decreasing the steam’s velocity too rapidly runs the risk of a pressure drop in the overall piping system, and potential safety valve malfunction.

Scarborough, Ontario-based manufacturer Stoddard Silencers of Canada wanted to develop a smaller, cost-effective vent-silencing solution that minimizes noise without sacrificing safety.

"Although we had a vent silencer design that works incredibly well, the size of it can sometimes be a hindrance,” explains Jennifer Lockhart, CEO, Stoddard Silencers of Canada. “Our sizing is based on temperature, flow and pressure of steam, and our internal calculations determine the required size of the unit based on our design along with those operating conditions. Unfortunately, our current design can get very big. We wanted to create a design that could reduce the required size. This would cut down on costs, as transporting these vent silencers can get quite pricey when we get into the really big sizes."

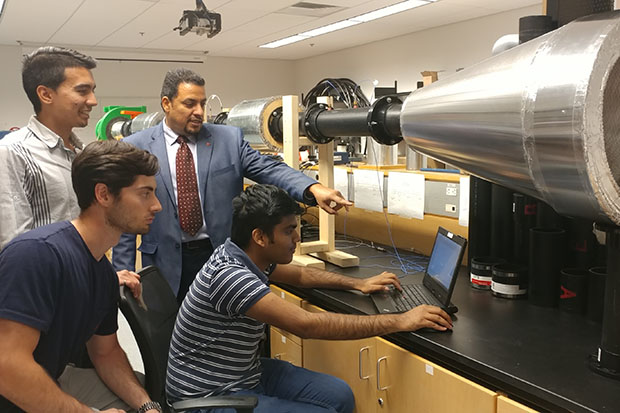

The company consulted University of Ontario Institute of Technology researcher Atef Mohany, PhD, Associate Professor, Faculty of Engineering and Applied Science. Together with Mechanical Engineering master’s students Karim Sachedina, Thomas Lato and Mdrashidul Islam, Dr. Mohany created a prototype for a streamlined and acoustically absorptive cone-shaped attachment for Stoddard’s vent silencers.

“The new technology increases acoustic attenuation (ability to scatter and absorb sound waves) of existing vent silencer designs by up to six decibels, with no pressure drop in the pipes,” explains Dr. Mohany. “Our vent silencer is much smaller than any other models currently in the market and provides similar levels of noise attenuation.”

Stoddard Silencers is evaluating the technology to determine its effectiveness and patentability, if they decide to adopt it.

“We were impressed with Dr. Atef Mohany’s professionalism, amazing patience, work and guidance, all key factors in making this project a success,” says Lockhart. “We credit Dr. Mohany’s innovative mindset and consistent communication for delivering on the research and development milestones both of our organizations agreed upon.”

The project received funding through a Natural Sciences and Engineering Research Council of Canada (NSERC) Engage grant, and the Ontario Centres of Excellence Voucher for Innovation and Productivity (VIP) program.