Ontario Tech innovating rapid PPE production solutions to address health-care shortage

New face shield will be in use within days; other protections and ventilators to follow

March 27, 2020

As part of the community response to the COVID-19 pandemic, Ontario Tech University is working with its faculty, industry contacts and local hospitals to come up with short-term solutions to help fill the critical shortages of personal protective equipment (PPE) available to front-line health-care staff.

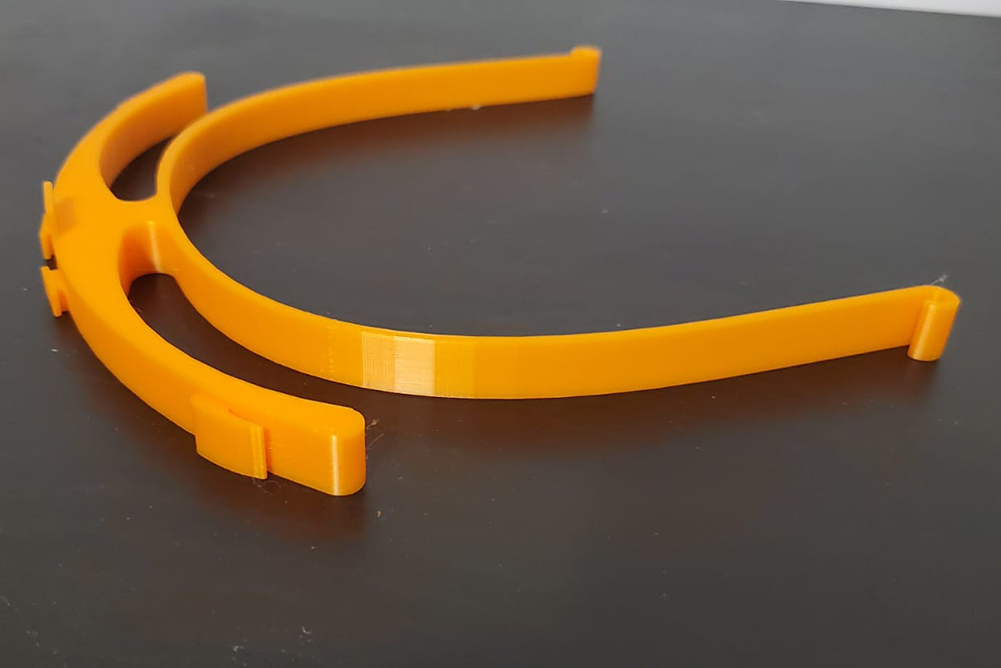

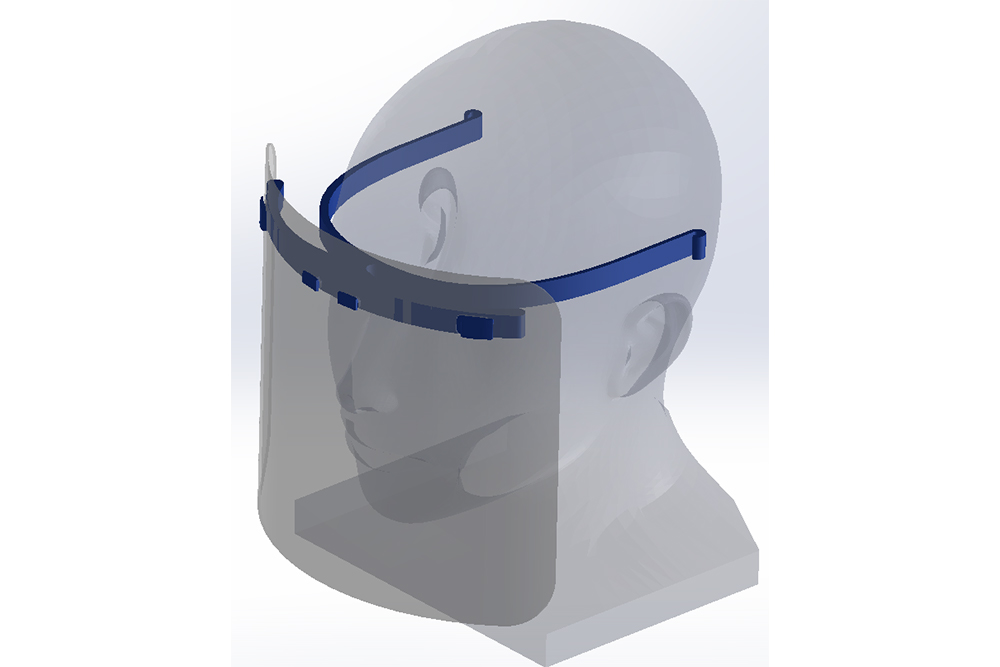

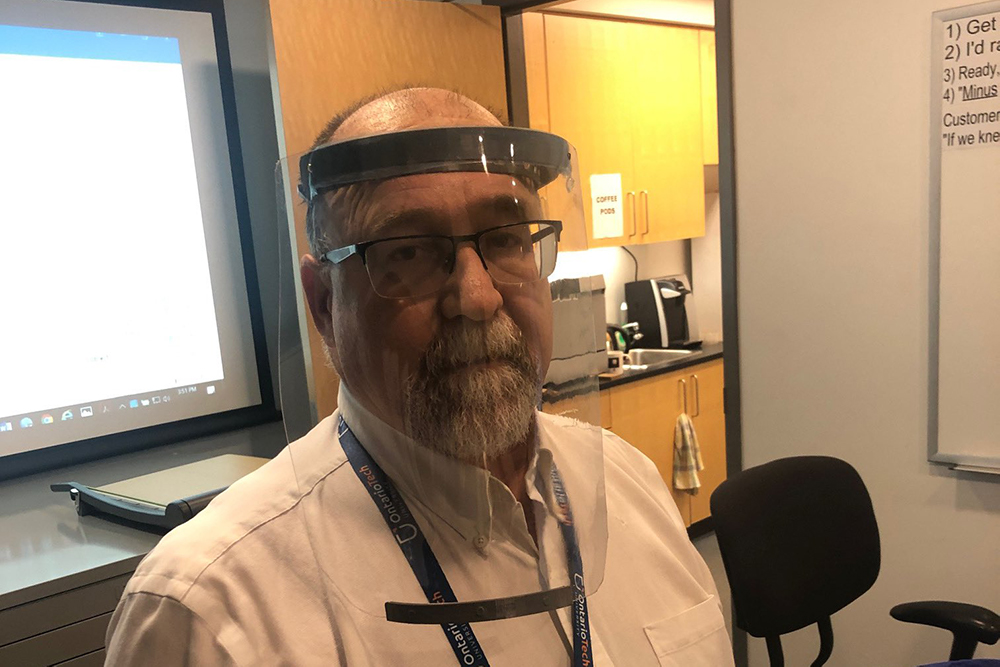

Ontario Tech’s faculties of Engineering and Applied Science (FEAS) and Health Sciences (FHSc) and ACE are developing, modifying and clinically validating designs for face shields that can be produced locally/regionally using flexible and agile manufacturing processes that involves crowdsourcing locally available 3D printers. The first prototypes were manufactured March 25, with assessments now underway.

First facemask design starting clinical assessment; another in development

ACE, along with its partners from the Automotive Parts Manufacturers Association, has initiated prototyping of two different facemask designs at Ontario Tech.

This first design is based on an open-source prototype designed by Guelph, Ontario-based InkSmith. InkSmith’s design received Health Canada approval during the week of March 23. In addition, Ontario Tech’s own design, also prototyped, will be developed with Lakeridge Health. Ontario Tech’s design is relatively light, easily 3D printable, and can be assembled in minimal time.

The second is a design originally developed by Johns Hopkins Medicine, can be manufactured on-site at hospitals. The prototype will be part of clinical assessments led by Ontario Tech’s FHSc. If successful, Ontario Tech will work with industry partners to develop assembly ‘kits’ that can be sent to health-care facilities.

Ontario Tech multidisciplinary research expertise contributing to solutions

Researchers* supporting the project development include:

Faculty of Engineering and Applied Science

- Ahmad Barari, PhD, Associate Professor

- Sayyed Ali Hosseini, PhD, Assistant Professor

Faculty of Health Sciences

- Shilpa Dogra, PhD, Associate Professor

- Adam Dubrowski, PhD, Canada Research Chair in Health-Care Simulation and Professor

- Mika Nonoyama, PhD, Assistant Professor

*watch for a future item about specific research activities in the Ontario Tech University news section.

Research partners

Last fall, Ontario Tech was rated No. 1 by Research Infosource Inc. for cross-sector research among Canadian primarily undergraduate universities. Some of these partnerships were successfully activated for the PPE production cause.

Partners committed to supporting Ontario’s health care teams include the Autonomous Vehicle Innovation Network (AVIN) led by Ontario Centres of Excellence, the Automotive Parts Manufacturers Association, automotive original equipment manufacturers (OEMs), major Ontario based Tier-1 suppliers, the Organization of Canadian Nuclear Industries and Ontario Power Generation.

- Related link: Ontario Power Generation's 3D printers producing face shields to protect health-care workers (OPG news release, April 2, 2020)

Quote

“We’re all working against the clock, and the past few weeks have drawn the Ontario Tech University community together in new ways to help in the fight against COVID-19. We have a ‘can-do’ spirit here at Ontario Tech, and I’ve been so impressed with how quickly people across our campus have mobilized with our external partners to not just come up with ideas, but actually make them happen. Innovative design and manufacturing techniques like those used in this mask production can make a real difference in this fight.”

-Dr. Steven Murphy, President and Vice-Chancellor, Ontario Tech University

4 > 1