Ontario Tech partnership to help safeguard nuclear reactors from earthquake damage

Mechanical Engineering researcher Dr. Atef Mohany collaborating with Curtiss-Wright Nuclear Canada

March 9, 2020

One of the most important safety considerations of nuclear power plant design is a facility’s structural capacity to withstand the possibility of an earthquake. In the event of any seismic activity, the structural integrity and survivability of components is paramount. In the event of extreme seismic activity, reactors need to able to shut down safely.

This area of research, known as seismic qualification, helps the nuclear industry apply the latest technologies to develop of equipment that meets and exceeds the most stringent safety standards.

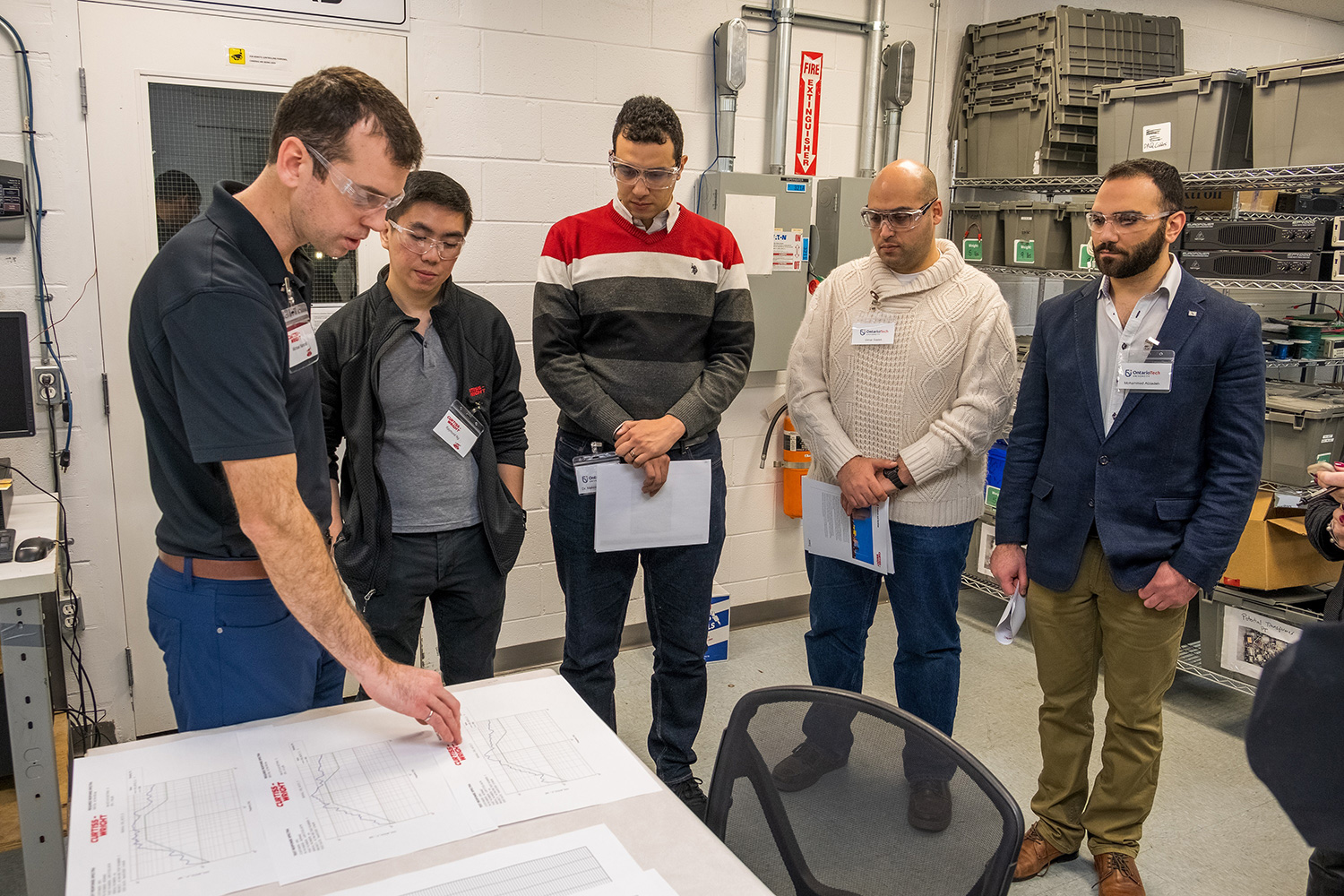

At Ontario Tech University, Mechanical Engineering researcher Atef Mohany, PhD is collaborating with high-tech industry component supplier Curtiss-Wright Nuclear Canada (CWNC) to improve seismic qualification for the nuclear industry. Formerly with Atomic Energy of Canada Limited, Dr. Mohany brings a wealth of industry experience to the collaboration.

Through seismic test simulations, the partnership aims to safeguard nuclear device operation during earthquake events, including shutting down a reactor if required.

How does seismic qualification research work?

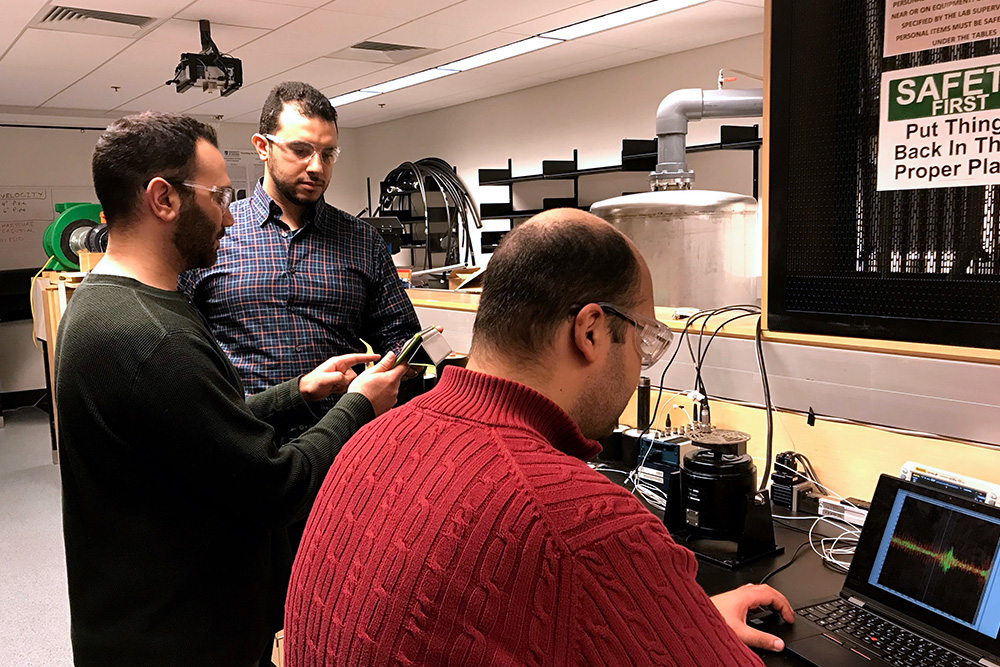

At its facility in Newmarket, Ontario, CWNC has a three-direction (triaxial) shaker table that physically simulates ground vibrations to mimic seismic event scenarios. Engineers put the table in motion with various oscillations at different amplitudes and frequencies. For example, the table may move rapidly in the x-, y- and z-axes in a 15-centimetre range. Simultaneously, very small impacts may occur at higher frequencies.

Engineers record the time it takes for objects placed on the shaker table to come to rest (known as the ‘damping value’ or ‘damping ratio’). They also inspect objects on the table for signs of structural damage.

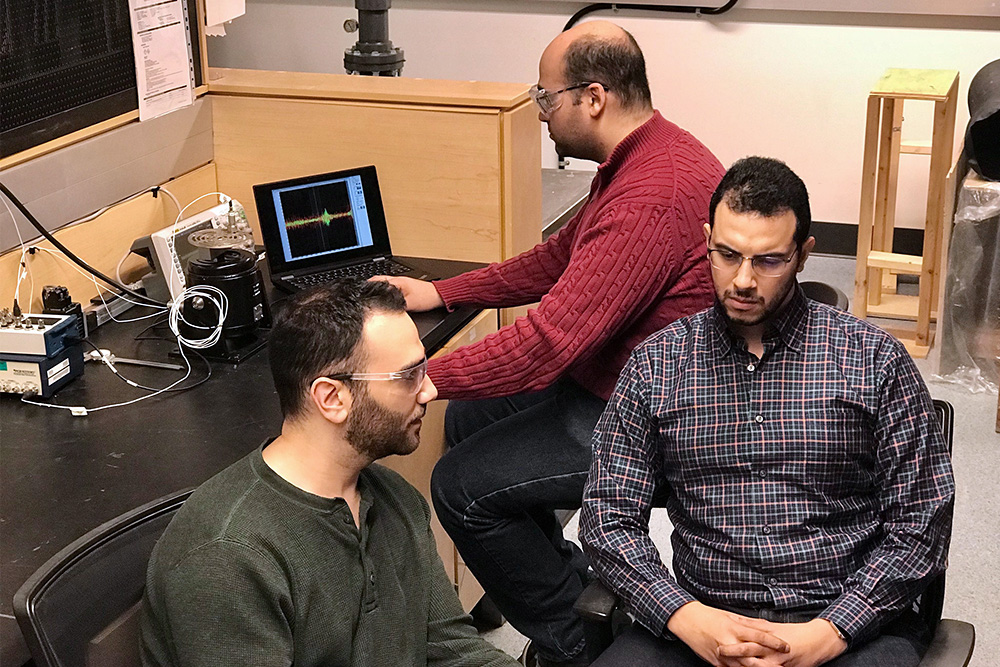

Several members of Dr. Mohany’s research group at Ontario Tech are involved in this project to gain more experience with industrial needs. His team includes post-doctoral fellow Mahmoud Shaaban, PhD, and doctoral students Omar Sadek and Mohammed Alziadeh.

The research team anticipates releasing preliminary findings by this November. Dr. Mohany’s research collaboration has also received a boost from the Natural Sciences and Engineering Research Council of Canada.

As CWNC aims to reinforce its market leadership position in the industry, in the longer-term, Ontario Tech and CWNC also hope to establish a strong relationship for further research projects. This includes developing opportunities for Ontario Tech graduates to work in CNWC’s domestic nuclear market.

Quotes

“Our collaboration with Curtiss-Wright Nuclear Canada is a powerful example how Ontario Tech University applies technology to help industry and community partners uncover innovative solutions to their most pressing problems. The data gathered from the seismic test simulations help reactor designers determine the structural strength required to withstand the power of tremors.”

- Atef Mohany, PhD, Professor, Faculty of Engineering and Applied Science, Ontario Tech University

“What we want to avoid is the concept of overtesting, which means an object on the seismic table is unintentionally subjected to higher excitation levels, leading an object to structurally fail. Our collaboration with Dr. Mohany at Ontario Tech University will help us understand the nature of overtesting and avoid getting bogged down with false-positive failures typically inherent with seismic qualification processes.”

- Mike Nanowski, Senior Project Engineer, Nuclear Division, Curtiss-Wright Nuclear Canada